Finding Problems, Resolving Problems

An eventful few days, largely dealing with wear and tear maintenance issues.

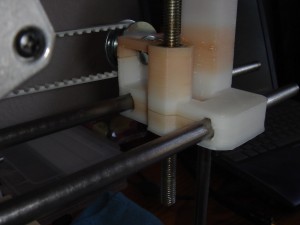

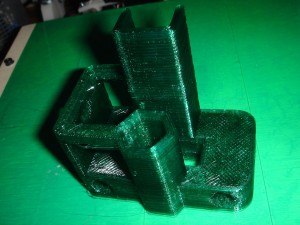

X End Idler Split

It seems that whilst using lubricant on the Z axis rods was a reasonable idea it soaked into the X End Idler and caused weakness between layers (I believe). This in turn resulted in a slight split and the head of the hot end ploughing through the last few layers of a print.

Attempting to realign the print (of a gear) seemed to work fine, but closer inspection shows it was pretty skewed and is not usable as it stands.

Luckily the split didn't grow, or affect subsequent prints, so I could print out it's replacement.

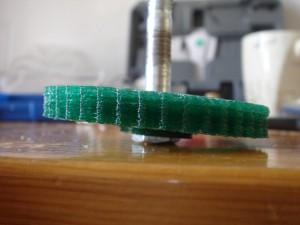

Perfecting the Pulley

So my circles were coming out oval and I still hadn't printed the perfect pulley. Suspecting that a replacement pulley with a dent in the teeth was the cause of the oval problem I brought the original out of retirement with a quick hack. This allowed me to print a few pulleys, and this time I achieved pulley nirvana. The secret? Cool in Skeinforge. It seems obvious now, but my previous attempts to utilise the cool module didn't work because I was using "orbit". Changing this to "slow down" meant that the spurs and teeth were laid down much slower, and hence with much less deformities!

Loose X Belt

Having more faith in the X pulley I was expecting perfect(ish) circles, but no joy. A bit more observation made me realise that the X belt was wobbling quite a bit at the apex of each turn. I had thought the belt was tight enough, but it seems it was not - and tightening it so it "twangs" when tapped results in much better circles.

Comments

-

Phil

22-05-2011 11:18

I find your site very helpful. Special thanks for visual instructions on Wade's extruder. I am building Prusa too but having problems with electronics. Btw how much did all of the electronic parts cost you?

-

Gary Hodgson

22-05-2011 21:46

Hi, I'm glad that the guides are helpful! Thanks for letting me know.

For the electronics I bought a Ramps v1.2 kit together with a Arduino mega 2560 from reprapsource. This came to €94 including shipping and tax. Then I got the Pololu stepper motor drivers from grrf.de which cost €40. The 5 stepper motors were ~€55 from Zapp Automation. So all in all these parts cost about €200 - perhaps a bit more including delivery.

Hope that helps.

-

Printing reprap pulleys : brelovich

04-04-2012 18:49

[...] pulleys would come out with one tooth missing or severely malformed. That is until I read about the Cool settings in Skeinforge. It turns out, if you activate cool, set a minimum time of 30 seconds or so per layer [...]

-

Manicarus

16-07-2014 04:23

Your troubleshooting was very helpful!

I managed to solve my problem after reading your article.

Because of my loose y-axis belt, my circle was really ugly.

But after reading this, circle comes out really pretty!! :) thanks!!!