Bamboo as an Alternative to PEEK or PTFE

Motivation

PEEK and PTFE are too expensive to use in experimental hot ends and quite difficult to come by.

Pros

- Cheap

- Readily available

- Easy to work with

Cons

- Irregular diameter

- May have properties yet untested that make it unsuitable

- (added 4 May 2011) Friction between filament and bamboo makes a squeaking noise. Doesn't seem to affect throughput or quality though. Update 2 (added 11 May 2011): The squeak seems to have gone. Perhaps now the bamboo is drier than before and this has caused it to go?

Build Process

- A piece of bamboo that cut from a plant last year was used, but one could find something suitable and cheap from a garden center. The key is to find bamboo thick enough that will allow a hole wide enough to hold your nozzle to be drilled in.

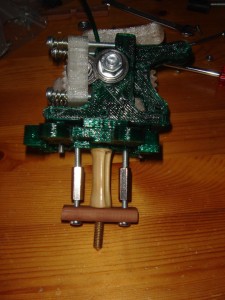

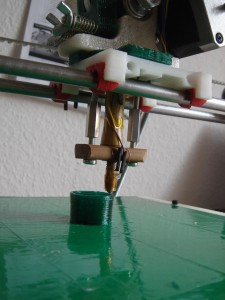

- The size of an individual segment seemed to work well, and simply cut at the first knuckle.

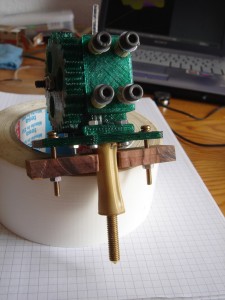

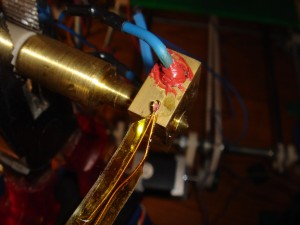

- A 3mm hole was drilled the length of the piece for the feedstock entrance, and then the nozzle end was widened by 5mm part of the way down (however far the nozzle should be screwed in).

- The feedstock entrance was reamed slightly to provide a wider opening for the feedstock to find its way.

- Wetting the bamboo makes it slightly flexible, so before screwing in the nozzle the entrance was soaked under a tap. This may or may not really help, but so far the nozzle in the test pieces have remained tight and secure.

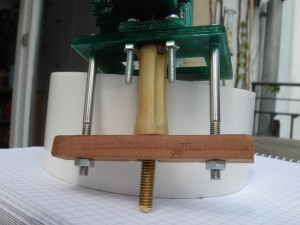

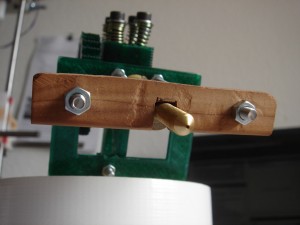

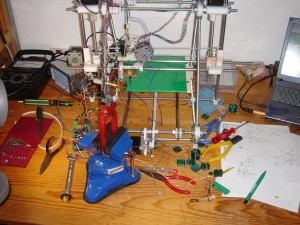

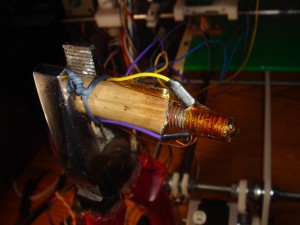

- Several means of attaching the hot end to the extruder were explored. Shown here are several T-bar approaches, and one which utilises the non-symetric nature of the bamboo to create a type of twist-lock mechanism.

- Holder, NiChrome wire (a heating block would also work) and thermistor were installed.

- Attachment to the extruder body utilised the DB adaptor by danieldb2. To help guide the filament another small piece of bamboo was whittled into a funnel.

Test Method 1

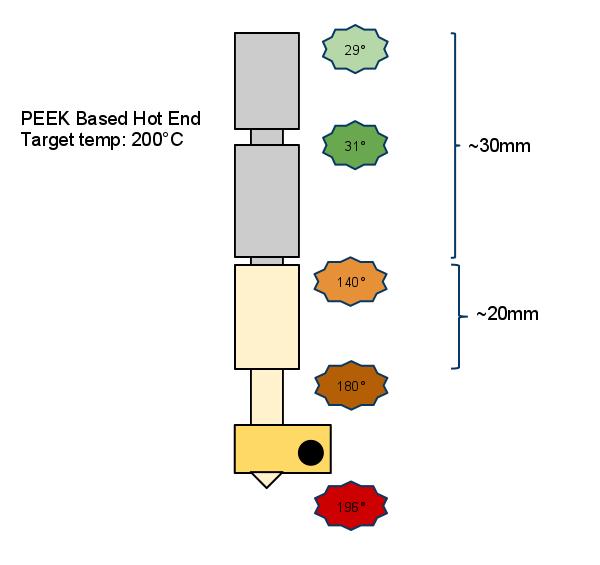

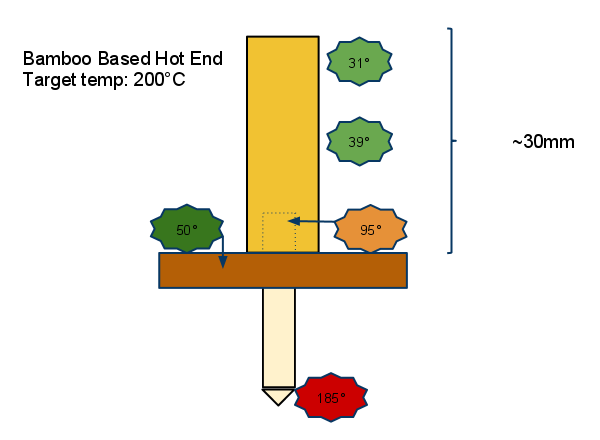

With the hot end in a vise and connected to the RAMPS, and using a thermistor connected to the bed temperature pins of the RAMPS board as a probe, measuring the temperature at various points. This is very imprecise as can be seen by the fact the nozzle thermistor read 200°C but the external "probe" read between 185°C and 190°C, but gives an indication of how the hot end reacts. It also is usful when compared with a PEEK based hot end.

Results

Test Method 2

Printing objects as part of a standard reprap setup.

Results

So far the hot-end has seemed to work with no problems. The big question is if this continues over the longer term, and whether it handles bigger prints with longer print times.

Comments

-

NumberSix

10-05-2011 22:27

Excellent use of a natural material. I've been searching of alternatives to PEEK myself and this is one worth trying out. What material are you using for the horizontal block?

-

Gary Hodgson

10-05-2011 22:50

So far it seems to be working well - I completed some larger prints at the weekend and there were no heat-related issues at all. The cross bar is a piece of scrap wood I found in the garage, i'm not even sure what kind, but that too seems to be acting as a good insulator. The next version I build will probably use bamboo for the cross bar too.

If you do get a chance to try it out please let me know your results. One of the "issues" of using natural materials is the lack of repeatable consistency between parts, something one doesn't suffer with an artificial material like PEEK. So I will be very interested to hear if others have similar success.

-

Quentin

26-11-2011 07:41

You could use a free sample of bamboo flooring for the horizontal part and possibly other pieces as well.

-

Gary Hodgson

26-11-2011 11:22

Good idea. Once one can start using common materials the opportunities for finding sources and alternatives increases!