Improved Calibration of Extruder

After finding the Extruder Steps Calculation Spreadsheet on the brokentoaster blog I calibrated the extruder to produce better results. The important thing it seems is to measure everything on your own gear, and don't take it for granted that the default settings will just do.

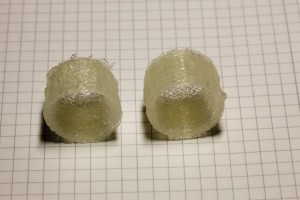

My gear ratio is 3.55 (not 5); the extruded filament diameter is more like 0.9 mm (not 0.5, although I will measure this again tomorrow); the Pinch Wheel Diameter (PWD) is 6.7 mm (not 8) and the steps per revolution is 3200 (after taking into account the 1/16 microstep setting). Consequently, the E_STEPS_PER_MM comes out at 48.5 according to the spreadsheet, a much higher value than the original setting of 22 in the Tonokip firmware I am using. The initial results seem much better. Still much room for improvement - but I was able to print a (rough) replacement end-stop holder, after my Z axis holder broke from over-zealous tightening last night.

Hopefully I will find time to formulate the process I went through and add it to the wiki, or add to an existing page if it already exists. I think these calibration steps, together with getting the right firmware/host combination, is a potential sticking point for newcomers, and providing clear directions and help would really help.